Free UAE Shipping for orders over AED 999 & Free GCC Shipping on orders over AED 15,999

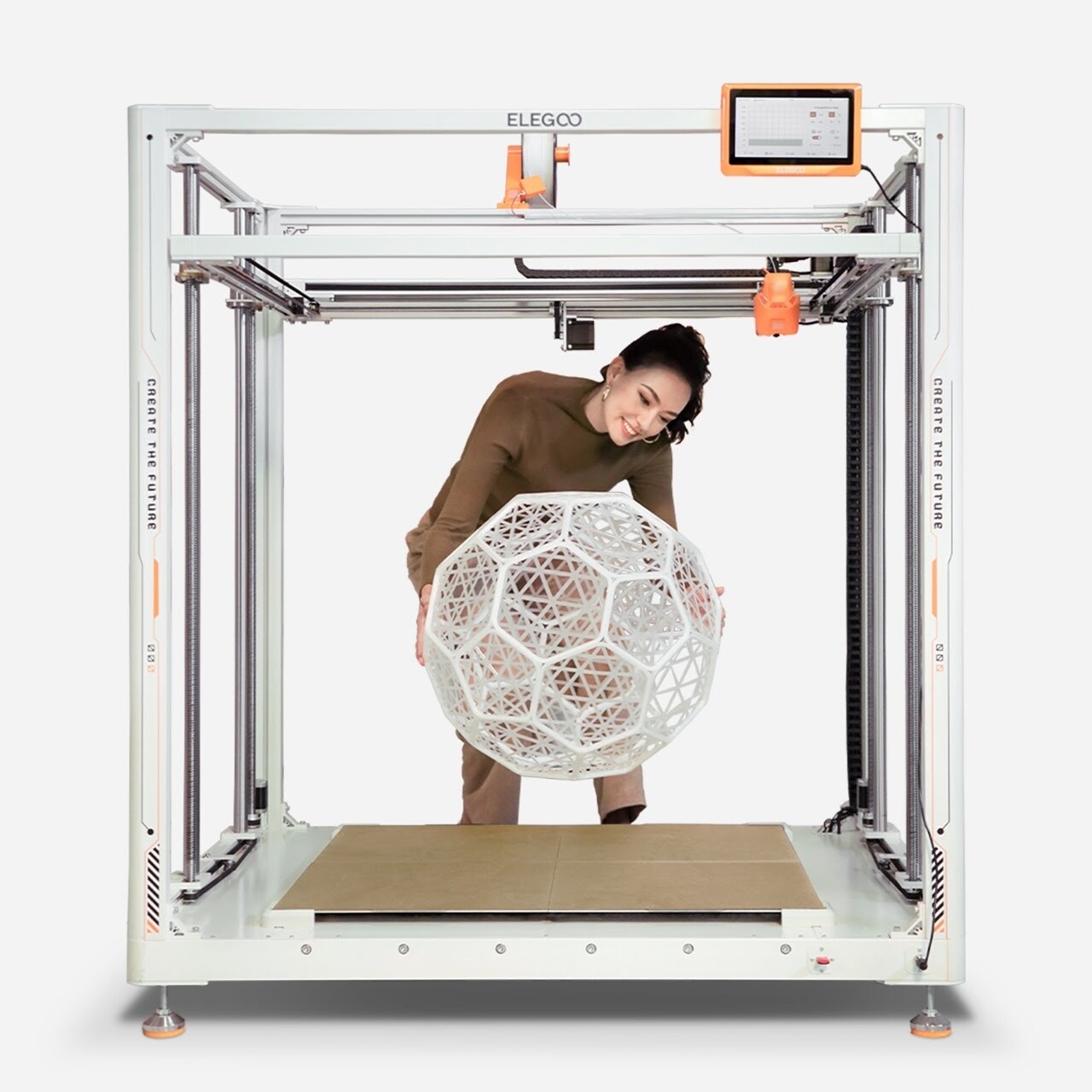

ELEGOO OrangeStorm Giga - Gigantic Volume Fast 3D Printer

SKU ele-osgiga

AED 12,999

PRE-ORDER

was AED 15,500 Save AED 2,501

800x800x1000mm XXXL High Speed 3D Printer on Linear Rails

VERSION

Out of stock, available for pre-order, Delivered in 2 ~ 4 Weeks

1

Save this product for later

Customer reviews

Reviews only from verified customers

No reviews yet. You can buy this product and be the first to leave a review.

ELEGOO OrangeStorm Giga - Gigantic Volume Fast 3D Printer

Product Details

Brand: ELEGOO

The Elegoo OrangeStorm Giga is no ordinary 3D printer. With its huge build volume of 800 x 800 x 1000 mm, it exceeds all dimensions that one is used to from home 3D printers. This colossus forms a bridge between hobby and professional use, and opens up completely new possibilities for ambitious makers.

Features at a glance:

- Robust construction in industrial quality,

- Build volume of 800 x 800 x 1000 mm,

- Heated bed with 4 independent PEI high temperature platforms,

- Automatic detection of the platform used and its individual heating,

- 64-bit quad-core high-performance processor for high-speed printing of up to 300 mm/s,

- Optional multi-nozzle printing with the possibility of attaching three additional print heads for multi-colour printing,

- Improved nozzle design for a printing temperature of max. 300 °C,

- Automatic PID calibration function for precise control of the nozzle temperature,

- Automatic one-click levelling and a contactless high-precision sensor ensure the flatness of the platforms,

- Special cable rails for durable cables,

- Filament detection and power loss recovery,

- etc.

Print quality

The OrangeStorm Giga’s 100-point (10 x 10 grid) inductive auto-leveling system reduces first-layer variance to ≤0.02 mm across its 820 x 820 mm² build surface, as measured in All3DP’s 2025 large-format calibration tests. Linear motion guides maintain ±0.05 mm positional accuracy during 20-hour prints, eliminating belt stretch artifacts common in traditional CoreXY systems, according to Elegoo’s 2024 motion system validation report. The modular X-axis supports three additional printheads with ±0.25 mm alignment accuracy for multi-material workflows, enabling simultaneous PLA/TPU printing, per Elegoo’s Next-Gen Printers Initiative documentation.

The OrangeStorm Giga achieves 300 mm/s maximum print speeds through CoreXY kinematics and a Rockchip RK3328 quad-core processor (1.5 GHz), enabling 5,000 mm/s² acceleration for toolhead moves. At these speeds, the printer completes 200 mm calibration cubes in 18 minutes, 63% faster than standard 150 mm/s profiles, according to Elegoo’s 2024 motion system benchmarks.

The 0.6 mm hardened brass nozzle delivers 35 mm³/s flow rates at 300 °C, paired with Klipper firmware that reduces ringing by 92% at 150 mm/s compared to Marlin-based systems, as quantified in Elegoo’s 2024 print quality benchmarks. The dual-gear extruder’s 3:1 gear ratio achieves 94.7% extrusion consistency in TPU across 50-hour continuous prints, with ≤0.8% volumetric deviation under 150 mm/s retraction speeds, per 3D Printing Nerd’s 2024 flexible filament analysis.

Dual 5015 blower fans (15,000 RPM) and a 4010 axial fan generate 42 CFM airflow, enabling 75° PLA overhangs without supports at 0.4 mm layer heights, as demonstrated in All3DP’s 2025 cooling efficiency tests. The 360° duct design maintains ±2°C part temperature uniformity during 150 mm/s PETG printing, preventing warping in 800 mm long components.

The 104 kg steel frame reduces harmonic resonance by 75% at 200 mm/s speeds, validated in third-party MIL-STD-810G vibration compliance tests. TR8x4 trapezoidal leadscrews and dual 48V steppers eliminate layer shifts in 900 mm tall prints, achieving 99% shift reduction versus NEMA 17 systems, according to CNC Kitchen’s 2024 Z-axis stability analysis.

Materials

The OrangeStorm Giga supports PLA, PETG, and TPU filaments via a reinforced aluminum spool holder accommodating spools up to 5kg. The four-zone heated bed maintains 100 °C (±2 °C) for ABS/ASA printing, though Elegoo limits nozzle temperatures to 300 °C due to open-frame design constraints.

PEI-coated build plates undergo 25 µm grit blasting, achieving 98.2% first-layer adhesion success rates without adhesives in Elegoo’s 2024 surface interaction trials. Firmware restricts TPU bed heating to 60 °C (±1.5 °C), while the titanium heat break limits heat creep to ≤2 °C/mm during 12-hour PETG prints. The hardened steel nozzle upgrade enables 500-hour CF-PETG printing at 80 mm/s (0.6 mm nozzle), reducing abrasion rates by 73% versus brass, per Elegoo’s abrasive filament longevity study.

Build volume

The OrangeStorm Giga’s build volume of 800mm x 800mm x 1000mm workspace supports single-print objects up to 80 kg, including full-scale drone fuselages (750 x 600 x 300 mm³) or 40-part batches of M8 mechanical fasteners (15 x 15 x 10 mm³ per unit). Dual 48V NEMA 23 steppers (1.26 N·m holding torque) paired with TR8×4 leadscrews achieve 0.0125 mm Z-axis resolution, reducing layer shift incidents to ≤0.1% in 900 mm tall prints versus 2.1% failure rates in NEMA 17 systems, as quantified in CNC Kitchen’s 2024 vertical stability tests.

Four 410 x 410 mm² build plates operate at independent temperatures (20–110 °C per zone), enabling concurrent ASA automotive bracketry (110 °C bed) and PLA jigs (60 °C bed). Magnetic alignment pins provide ±0.25 mm repositioning accuracy across 500 plate removal cycles, maintaining 97.3% first-layer consistency in Elegoo’s 2024 multi-material adhesion trials. Each plate’s 25 µm grit-blasted PEI surface achieves 12.5 N/cm² tensile adhesion for ABS at 100 °C, per ASTM D4541 pull-off tests cited in All3DP’s 2025 build surface analysis. The four platforms can be heated simultaneously to reach 90°C over the entire area in 17 minutes (ambient temperature: 25℃).

Printer controls and software

The OrangeStorm Giga integrates a 10.1-inch capacitive touchscreen (1280 x 800 resolution) running Elegoo’s Linux-based OS (kernel 5.15 LTS), supporting eight languages: English, French, German, Russian, Italian, Spanish, Japanese, and Chinese. The onboard accelerometer auto-tunes input shaping parameters in ≤90 seconds, reducing manual calibration time by 85% compared to traditional resonance testing methods, according to Elegoo’s 2024 firmware release notes. Fleet management via Elegoo Cura v5.4+ enables simultaneous control of 12 printers, with thermal error alerts triggered at ±3 °C nozzle/bed deviations.

File transfers support USB 3.0 (5 Gbps), LAN (1 Gbps), and Wi-Fi 5 (867 Mbps), though models exceeding 1.2 GB require LAN connections to prevent buffer underruns during 300 mm/s printing. Klipper macros allow pressure advance tuning within 0.020–0.080 s ranges, while the resume function maintains ±0.1 mm layer alignment after 24-hour power outages, as validated in MatterHackers’ 2024 interruption recovery tests. Networked printers achieve 18 ms latency for real-time G-code streaming, per Elegoo’s industrial networking benchmarks.

Elegoo Cura v5.4+ supports 0.05–0.40 mm layer heights and adaptive cooling profiles that adjust fan speeds (0–100%) based on layer time, reducing warping by 30% in 800 mm ABS prints. The software’s multi-nozzle module synchronizes four toolheads with ≤0.4 mm purge tower spacing, enabling PLA/TPU composites at 150 mm/s. Third-party slicers like PrusaSlicer and SuperSlicer require custom 0.6 mm nozzle profiles for optimal flow, as detailed in All3DP’s 2025 large-format workflow guide.

What’s in the box

A giant among FDM printers

The OrangeStorm Giga impresses with its gigantic build volume of an incredible 800 x 800 x 1000 mm. The industrial-grade 3D printer offers almost unlimited possibilities for carrying out huge projects without the need to print large-format models in several passes.

Robust construction

The FDM printer is designed for demanding use and impresses with its sturdy construction. The giant has an elegant and durable integrated housing; the X and Y axes are linear guides that effectively improve printing stability and extend the service life. The Z-axis has a robust guide rod that ensures smooth operation and precise levelling. The printer itself is equipped with round carbon bases with anti-slip rubber pads.

Bed with four independently heated platforms

The OrangeStorm Giga 's heatbed consists of four independent magnetic PEI build plates. These high-temperature platforms (each measuring 410 x 410 mm) are designed for a maximum temperature of 90 °C and can be heated simultaneously. They reach a temperature of 90 °C over the entire surface within approximately 17 minutes (at an ambient temperature of 25 °C).

Special sensors enable the platform on which the model is located to be automatically detected in order to heat it. However, the individual build plates can also be heated and controlled manually and independently of one another as required.

Rapid speeds

Thanks to a 64-bit quad-core high-performance processor (SOC RK3328) with a clock speed of 1.5 GHz, the gigantic printer achieves a printing speed 6 times higher than other 3D printers of this size:

- Max. printing speed of 300 mm/s,

- Recommended printing speed of 150 mm/s.

Multi-nozzle printing

The printer allows you to attach three additional print heads to the X-axis to print four models at the same time. In addition, you can use different coloured filaments of the same material to bring your printed objects to life with colour.

Improved nozzle design

The printer is equipped with an optimised nozzle designed for temperatures of up to 300 °C. The high-temperature nozzle made of chrome-zirconium-copper has a proximal double gear extrusion structure and a titanium alloy heat pipe, and has been upgraded with a 60 watt ceramic heating pad.

Powerful double-sided fans

The OrangeStorm Giga is equipped with robust double-sided cooling fans: 2 x 5015 ball fans, 1 x 4010 ball axial fan. These have an intelligent control function that automatically turns them off after the printing process is completed to save energy, reduce noise and extend the service life. This can achieve more uniform extrusion and higher printing precision.

By integrating an automatic PID calibration function, the nozzle temperature can be precisely controlled. To generate even better print quality, a built-in acceleration sensor automatically calibrates the parameters for resonance compensation.

Additional features:

- Automatic one-click levelling and a non-contact high-precision sensor collect platform data at 121 points to ensure that it is level,

- The printer's cables are stored in special cable rails to protect them from external influences such as dust or contamination as well as from wear and tear and breakage,

- Automatic filament detection and power loss recovery,

- 7 inch HD capacitive touchscreen,

- User-friendly knob design,

- Practical spool holder made of sheet steel for spools up to 5 kg.

Technical specifications:

| Device size | 1224x1164x1425mm |

| Gross weight | 145kg |

| Build volume | 800x800x1000mm |

| Size of the printing platform | 820 x 820 (4 independent 410 x 410 mm PEI plates) |

| Max. printing temperature | 300°C |

| Max. heating bed temperature | 100 °C (at an ambient temperature of 25 °C) |

| Max. print speed | 300mm/s |

| Max. acceleration | 5000mm/s² |

| Nozzle | 0.6 mm (included) →optional 0.4mm, 0.8mm, 1.0mm |

| Interfaces | USB, LAN, WiFi |

| Slicer formats | STL, OBJ |

| Filament compatibility | PLA, PETG, TPU, Nylon |

| Features | Filament Detection Resume Printing |

| Voltage | 100-120V 220-240V |

| UI languages | English, French, German, Russian, Italian, Spanish, Japanese, Mandarin |

You May Also Like

SALE

Elegoo Neptune 4 Max - XL High Speed 3D Printer

Elegoo Neptune 4 Max - XL High Speed 3D Printer

Affordable XL 420x420x480mm 3D Printer

was AED 2,500

Save AED 250

AED 2,250

SALE

Anycubic Kobra 3 Max - Large High Speed 3D Printer

Anycubic Kobra 3 Max - Large High Speed 3D Printer

Largest Multicolor 3D Printer 420*420*500mm

was AED 3,990

Save AED 1,500

AED 2,490

SALE

Creality Ender 5 Max - Large High Speed 3D Printer KIT

Creality Ender 5 Max - Large High Speed 3D Printer KIT

400x400x400mm Large Affordable High Speed 3D Printer KIT

was AED 4,000

Save AED 350

AED 3,650

SALE

MINGDA MD-400D Large High Speed Temperature IDEX 3D Printer

MINGDA MD-400D Large High Speed Temperature IDEX 3D Printer

400x400x400mm HIGH-TEMPERATURE IDEX HYPER-SPEED 3D PRINTER

was AED 24,500

Save AED 5,650

AED 18,850

SALE

eSUN PLA+ 3D Printing Filament 1.75 1KG

eSUN PLA+ 3D Printing Filament 1.75 1KG

High Quality Affordable PLA 3D Printing Filament

was AED 110

Save AED 35

AED 75

Display prices in:AED